Most of what we know of axes in the the US and Europe has come from our own traditions. In fact, even those things that we think come from long standing traditional use, have only been fairly recent developments. As such, our perspective can be limited.

Recently I had a discussion about Eastern European axes on a forum. The issue was trying to figure out the use of a Bulgarian axe based on its features. The problem of course was that we were doing that by applying what we know of design features on American axes. The two don’t always coincide. Many of the axes we used to use back in Bulgaria were the way they were just because that was all that was available to us. Having the best features for the task wasn’t really a choice. So, to determine why an axe has particular features, we have to look at the traditions of that country, not just superimpose our own understanding based on our traditions.

Well, luckily, a reader emailed me with some information from a Russian source on axes. It is an article titled Taiga Axe (Таежный Tопор), written by Igor Shipulin (Игорь Шипулин) in 1982 in issue No10 of the magazine Fishing and Hunting (Охота и Oхотничье Xозяйство). Here is the article as translated by one of the readers of this blog, which is much appreciated. You can see the original republished at the St. Petersburg Hunter here. As a reader pointed out, Russian axes and Eastern European axes are not necessarily the same and do have different histories and evolutions, but the information was still interesting.

Taiga Axe (Таежный Tопор) by Igor Shipulin (Игорь Шипулин)

For the hunter in the taiga there is no getting by without a dependable axe, which must be as versatile as possible. On the market are many axes: from large and medium construction-carpentry axes to smaller hatchets suitable for various household needs. But the taiga axe must have special properties, which can be imparted to an ordinary axe by reshaping.

An axe with soft steel and poorly hardened is to be preferred to an axe with "dryish" steel. If the bit tends to chip, this shortcoming is easy to resolve with a steeper grind. The profile of the grind must be convex, not concave and not straight (fig. 1). An axe with such a grind does not jam in the wood, splits logs well, dulls less. With adequate sharpness such a blade is more than suitable for carpentry work.

Much in the understanding of design rationale is evident in the shapes of old Russian axes, as well as the axes of lumberjacks in the Carpathians, and in North America, on which the blade's upper edge never forms an angle greater than 90° with the haft's axis. All the axes now produced for the market have a wide blade and a protruding upper edge (fig. 2). The shaded portion dramatically reduces the axe's efficiency, as this portion tries to straighten the haft at the moment of impact, creating needless vibration, and thus dampens the force of the blow. To eliminate this deficiency, the shaded portion is removed. This is easy to do by drilling a row of contiguous holes along the cut line, removing the hardened portion by abrasive means.

It is necessary to modify a straight blade edge to a curve (fig. 3), if the width of the hardened part allows.

A straight edge is suitable only for carpentry tasks. When such a blade chops, making contact all at once with the entire edge and hitting the wood at a right angle, it has little penetrating ability. With a curved edge, every point enters the timber at an acute angle (fig. 3) and creates a slicing effect, sharply increasing the penetrating ability of such a blade. Even as the weight of the axe is decreased after modification, its efficiency is increased.

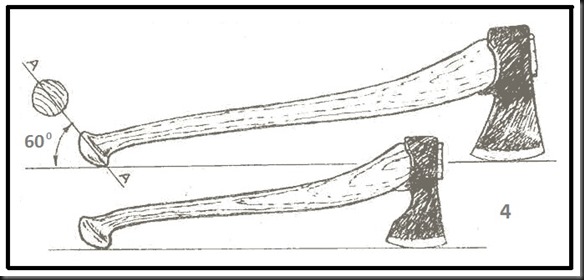

The author proposes two axe variants (see fig. 4 & photo). One is lighter, intended for mobile hunts and smaller trips, as well as commercial hunts when used with a saw. Total weight of such an axe: 800-1000 g (28-35 oz); haft length: 40-60 cm (16-24 in). The other is heavy, for commercial hunts and long trips, during which it is necessary to carry out major tasks. Its weight: 1000-1400 g (35-49 oz); haft length: 55-65 cm (22-26 in). The choice of haft length is determined by the timber's quality and the hunter's height and strength.

Having modified the axe head, the haft can now be fashioned. It must be thin. The lighter it is in relation to the head's weight, the greater the impact. It must be flexible: a rigid haft "dries" the hand. In cross-section it has a flattened oval shape with a thinner front edge and rounded back edge.

Ideally the haft should be made from the butt end of ash, maple, or elm. It can also be made from curly fine-grained birch. The most suitable butt thickness for making an axe handle is 35-40 cm (14-16 in). The raw stock should be split and then dried with sealed ends.

A haft with longitudinally-oriented grain (fig. 5) is stronger. Before mounting the head, its center of gravity is found (fig.6). Typically this point (U) is located at the base of the eye. Next, the centerline AB [B is missing in the drawing] of the head is determined, going through the middle of the poll and the apex of the bit's edge. This line is a tangent, along which the axe will move at impact.

If we place the edge with point B on a plane perpendicular to the centerline AB, then the end of the haft must touch this plane at point C. On the haft's centerline PU, point P is spaced from plane CB by 3.5-4 cm. How the haft is to be cut is clear from fig. 5, where the shaded portions must be cut out of the stock. The distance from the lower end of the eye (point K) to the haft's maximum bend point (O) measures 10-11 cm. The hand holds the axe at point O during carpentry work. Here the haft's circumference is 12-13 cm, while the thinnest part is at the end of the haft - 9-10 cm around. The final thickness is customized to fit the hand.

The haft terminates in a hand-securing expansion in a "mushroom" shape (as you can see in the photo). Such a haft is indispensable in cold and rain, when gloves or mittens are worn. The "mushroom" allows the hands to relax at the moment of exertion. The power and accuracy of the blows of a "relaxed" axe are not equaled by the blows of an axe which must be gripped tightly out of fear of loosing it from the hands. The expansion for the "mushroom" is taken into account on the blank. It is fashioned last to keep from getting damaged when the head is mounted.

Getting to the mounting, it is necessary to situate the blank. As the haft is fashioned, the angle of the axe in relation to the plane (line CB on fig. 6) should be checked regularly. In the haft, fitted to two-thirds of the eye depth, a gap is made for the wedge to this same depth (fig. 7). After this, the final mounting fit is customized. Before the wedge is driven in, it is beneficial to dry the haft with head mounted for 2-3 days. Immediately after mounting (or after drying), the head is removed from the haft, fitted parts are liberally smeared with glue BF-2, and the head is finally mounted. Glue is again applied to the fitted wedge of hardwood (ash, maple, elm, apple, pear), and the wedge is driven in. So that the wedge doesn't break when it is driven, it is made short. For the glue to cure completely, the axe must be dried for several days on a heater or by a stove. Final shaping of the haft is done to fit the hand, and the haft is sanded and

permeated with varnish or linseed oil.

The completed axe needs only to be sharpened. The axe will save you much strength and time if its edge is always keenly sharpened. For this it is useful to carry a small wood slab cut to fit the breast pocket, with water-resistant sandpaper glued to both sides - coarse and extra-fine. This slab should easily last a whole season, if the axe does not require serious regrinding.

Big thanks to Leo for the translation. It certainly makes the article much more clear than it was with my original translation.

From what I understand, the author of this 1982 article is trying to provide guidelines for a good multi purpose axe for the taiga. The problem for the author is that at the time axes in Russia, both manufactured locally and imported were what we would call carpentry axes. That was not because that was their intended design and purpose, but was rather the result of scarcity and a number of historical circumstances which made this the dominant pattern for a wide range of uses. That was also my experience through 1995 when I came to the US. The author understands that these axes are used as multi purpose tools, but does not believe they are well suited for the task. The article should be viewed in the context of those available axes. Here is a good example of such an axe pattern that from what I understand, originated in Russia, and has been very common in Eastern Europe and used for everything from felling, to splitting, to carving:

The author more or less provides a tutorial on how to take an axe that these days in the US we would call a carpenter’s/carving axe and turn it into a multi purpose axe. He argues for the removal of any part of the blade that protrudes above a 90 degree angle above the handle. He also states that the blade should be curved rather than straight. See figures 2 and 3. The shades sections in those diagrams show the metal that should be removed.

The author recommends that the handle be carved from dry ash, maple, or elm. Those are much more prevalent woods in the area than the hickory to which we are accustomed. Figure 5 shows how the extract good grain handles from a large piece of wood.

Two sizes are recommended. When used together with a saw, or for shorter trips, the article recommends an axe that is about 16-24 inches long, with a head weighing 28-35 oz. Just for comparison purposes, that would be somewhere between a GB Small Forest Axe, and a GB Scandinavian Forest Axe. For longer trips, the author recommends an axe with a handle between 22-26 inches with a head weighing 35-49 oz. For comparison, that would range from a GB Scandinavian Forest Axe to a short handle full size axe.

Anyway, I just wanted to share with you this article as it takes a slightly different perspective on axes. Since the article was written, I think there has been a lot of effort put in by modern axe manufactures to produce all purpose axes, which in many ways resemble the ones described here back in 1982. If you wish to read more articles on the subject, just Google “Таежный Tопор”. For some good examples of people following the advise in the article and modifying similar axes, check out the post here, as well as the comments.

No comments:

Post a Comment