This is another post made by OPERATOR1975 on Blades and Bushcraft. This time the subject is the Collins company and their axes. It is full of great information, and actual pictures showing examples of the axes discussed.

This is a little history and pictoral on the Collins & Co axe maker. I have done manufacturing threads elsewhere that have gone over well, so thought I would share this one here too.

After you get done reading it, hopefully you can see why it took some time. A good portion of it was just rounding up my Collins axes for picture day.

This will be broken down into 5 sections as follows -

Name(s) and associated timelines

Influence and competition

Labels/patterns/handles

Business/advertising

Wrap up

So get comfortable, grab a delicious beverage(my nephew calls them "daddy pops"), and have some time on your hands - might be here awhile.

NAME(S) AND ASSOCIATED TIMELINES

Collins is one of the more familar names in the history of axes, and with good reason. One of the dominant manufacturers with axes, not only in the USA, but at its peak, in the world. There is a TON of information on a company this big and spread out over 140 some years, and one could easily write a book just on Collins(they have, lol). I will attempt to look at the "meat and potatoes" for us axe heads - hopefully we can all come out a little bit better.

Collins is perhaps one of the oldest axe manufacturers. They started in 1824-1826(depending on what you read and what you take into account). Other axe makers were around before sure, but none with the eventual size and influence of Collins.

Started by David Wells and his two cousins, Sam and David Collins in Canton, CT. As with almost all axe companies regardless of the time period, there were shake ups, reorganization, renaming, etc. This can be very confusing, I will try and keep it as simple as possible here - basically broke down into 3 main names - Collins & Co, The Collins Manufacturing Co, The Collins Company. Confusion already no doubt, but the timelines with each name went something like 1826-1834, (reorganize), 1834-1843, (reorganize), 1843-1966. As noted, they started in Canton CT, but with the popularity and size of the Collins plant, the town was renamed to Collinsville. We will discuss the different names on the axes, the towns, etc, and what they mean and why.

Collins, as mentioned, was a very successful company. They absorbed other axe manufacturers along the way, one most notebly being the Warren Axe and Tool Co in 1950-1955, depending on your source. Collins would eventually feel the pressure of the mighty chainsaw and overseas competition and eventually fall prey to the Mann Edge Tool Co of Lewistown Pa in 1966. METCo continued the Collins axe line due to its popularity. As time wore on though, not even METCo could survive, and was eventually sold and moved to Mexico via Truper Herramientas(Industries) in 2003. The Collins Axe name is still made by them today, though quality is no where near the same as what the great company once gave us.

INFLUENCE AND COMPETITION

As mentioned, Collins at its height was perhaps the largest overall axe maker in the world. It can be debated that Collins and Kelly were 1-2, or perhaps 2-1, depending on what you read from whom, etc. That is for another day. Collins influence on the axe world is undeniable. Early on (mid 1800s) as Collins and their name grew in popularity, out came other axe manufacturers to try and make money of similar names, logos, labels, etc. Collins wouldnt stand for this - and they took action directly with the government, and then also via themselves.

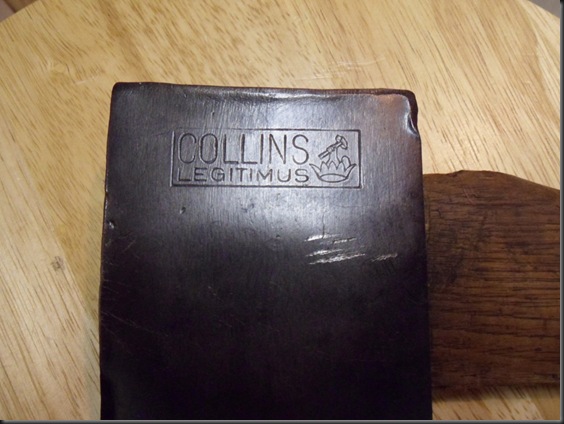

A quote from one of their catalogs I have - 1921 - "There are offered in the various markets of the world, axes, hatchets, and other tools with various imitations of our trade mark, which is COLLINS & CO. Some tools have been stamped B COLLINS, D COLLINS, or H COLLINS, and were made by American manufacturers. While others, principly made in Germany, either have exact imitations of our stamps and labels, or those which purposely bear a resemblance to them. For better protection of buyers against counterfeit goods, we adopted and registered an additional trade mark as follows: (Legitimus crown, arm and hammer logo), being a crown with arm and hammer over the motto : LEGITIMUS. All Collins tools are now stamped with this design. Buyers wishing this genuine should address the makers, or buy only of reputable houses. We would highly apprciate information leading to the conviction of any manufacturer or dealer making or selling spurious Collins goods. Such information would be held as strictly confidential." (You can read this later on in the catalog pic)

Legitmus Logo -

There are many many different styles of the Legitimus logo used over the years, and is still one of the most recognized axe stampings ever. I had never heard of the word Legitimus until Collins. Do yourself a favor and look up the meaning of it.

So as you can see, Collins recognized the threat, and took action with not only the Legitimus stamping, but then by also calling on the public. This I find fascinating. Wonder what manufacturer would do this today. Probably just sick a lawyer on someone.

Other influence came from Collins not only in the form of axes, but in various other tools. Collins was widely known for manufacturing hammers, wrenches, knives, machetes, hatchets, adzes, picks, mattocks, and plows, to name a few items. One can see with this overall line, name recognition, and loylaty, it was no wonder Collins took off in the market. Collins had multiple contracts with government and produced bowie/fighting knives in ww2, along with machetes and axes during the war.

LABELS/PATTERNS/HANDLES

Collins, as many axe manufacturers, used a huge variety of axe patterns, and then also labels and stampings. Some of these included :

Wise

R King

Root

Swift

Charter Oak

Homestead

Bonded

Legitimus

Red Seal

Commander

Thats no where near all of them, just some of them. Lets take a look at some -

Homestead :

Red Seal : (newer logo)

Legitimus : (couple variations)

Commander -

One thing that Collins did perhaps better than any other axe manufacturer was the detail on its paper labels. Some of the old Legitimus labels had spectacular graphics, raised lettering, colors, etc. This helped the buyer know it was indeed a true Collins. Hell it even had the signature of Sam Collins on it -

Obviously with an axe company this big - they had to think about handles. They made their own to meet their demand and specifications - this was not uncommon in axe manufacturing, but Collins did it perhaps as well as any other manufacturer -

Collins also as stated above was a major player in the world market. The sold axes, knives, machetes all around the globe, but had a heavy influence in Mexico and South America especially. So, with that, they had to make axes especially for that market -

Notice the paper label - it is in spanish. They produced these labels in english, spanish, portugese, and I believe what is known as mexican spanish, if there is indeed truly such a thing. I would guess this would be to reach out to local areas as needed. Also notice the axes themselves, and how they differed from the conventional american felling axe - no poll to speak of.

Pattern wise they made everything and anything it seems to meet and fit the needs of the buyer -

Undercutter -

Hewing -

And then even for the tobacco market -

Their presence in the axe world is undeniable as stated. I firmly believe one main reason for this is though how Collins dealt with our next section -

BUSINESS/ADVERTISING

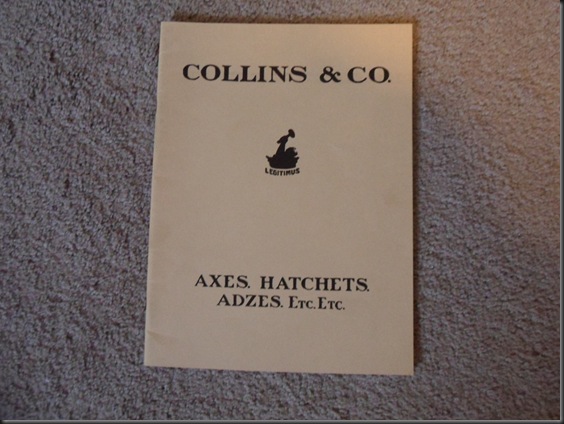

Collins was a supreme outfit when it came to getting its name out to the public. They recognized early on the importance of the best advertising, which is word of mouth. That being said, you can build word of mouth by building the brand, the aura of the product you are selling. They did very well at this. Collins was big into the catalog market -

The quote above about the frauds was from this same catalog - a reprint from 1921. You can see they were very very proud and almost oppressive about the Legitimus mark and quality.

Collins was also huge into the signing market - especially south of the USA -

This is the same sign, double sided with different wording on each side. Pic 1 states - Legitimus brand Collins Save using the best. Pic 2 states - Legitimus brand Collins They cut the best they last longer.

While signs in spanish and portugese seem to be more plentiful, there were of course english signs as well -

All 3 signs are relatively small, that is my pocket bushman I got off of fortytwoblades for comparison.

A thing to note is that we stated that the Collins plant was in Collinsville CT, but when you look at the signs and paper labels - they all say Hartford CT. This was due to the fact that Hartford was more well known globally then Collinsville. You will also see New York listed on some signage - this is due to the fact that they had an office in New York city. Also, lets not forget at their prime they had 4 major plants going - one in Collinsville, one in Mexico, one in Columbia, and one in Brazil. Their influence in south america is major as you can tell.

Also another way of advertising is through producing other lines for other companies or institutions -

You might of heard of this major institution - Boys Scouts (Collins - 1923-1936)

Front side of hewing hatchet -

Back side - stating W.U Tel Co - Western Union Telephone Co -

This undoubtedly helped to get the Collins name even more recognition.

As time went on though, and business literally went south, the company as we said eventually was bought out by Mann Edge Tool Co. Special note, as stated Collins had the four main plants - when they sold to Mann Edge, Mann bought the naming rights and the Collinsville CT plant. The other three plants were sold to a company you might have heard of - Stanley.

Mann Edge still tried to use the labels for advertising though - but obviously it wasnt the same as what it used to be -

This axe and hatchet are from the Mann Edge days - and upon inspection are of some pretty questionable quality. The axe has the made in use label, yet a marking for mexico on the back......

WRAP UP

Collins & Co will never be forgotten in the history of axes, that is for sure. Their presence, influence, and business tactics helped to set the stage for others as well. Just imagine what the company saw over its tenure from 1826 to 1966. In 1826 the USA had 24 states! Water was the major source of industrial power. We were 120+ years still from the first real impact of the chainsaw......

Collins gave us the Legitimus stamp - one of the most recognizable tool stampings ever. It was created to ward off frauds, while also showing a dominant untochable quality for the buyer. I can see many a buyer technically buying the stamp and wording, and the axe just happened to come along for the ride.

Collins was one of the first companies to recognize that if you used quality iron and steel you would get the ultimate payback from your customer base. They combined the two into one major tool behemoth that will live in the halls of axe history.

Thanks to yesteryear tools, catalogs, conversations/emails with Tom Lammond and Larry Mcphail, and some basic digging and research. Hope everyone liked this.

A revamped Kelly thread will be next.

Thanks!!!!!

![112[3] 112[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgXAp08RpfHzO-PWu3Tp6xsQevPawrDi4WbF1aJkgPMv7FuQltNwgPJoWt1a4q8-5Rg-7VoWkyzuraNPG2V8eRGs3CJJGecaUOp6vr5N43hGPYxTmM95BXi9b-Tx9vuJrDkVdu7vYIpcVA/?imgmax=800)